- Business

- Technology

- Process

- Product

![]()

Various departments discuss and decide the development themes to meet

our customers' needs and glass requirements, incorporating safety,

performance and environmental concerns.

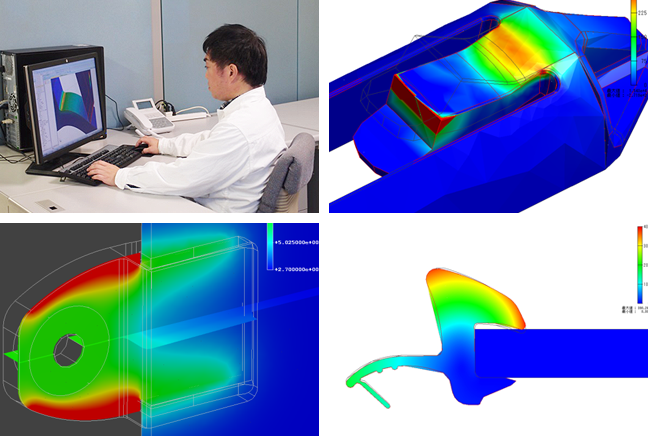

The product design process begins. Performance requirements are understood through

thorough discussions with our customers.

In this stage, the basic performance will be approved through simulation.

Resin parts are designed considering component quality and the comprehensive window

system which improves glass quality and functions as they are assembled to glass.

![]()

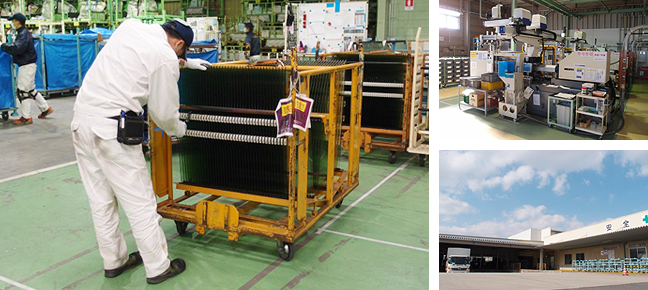

Prototypes are produced to check limit performance and verify performance results.

This is a critical process for material development.

Preparation for smooth mass production start up begins. Quality, cost, and time targets are set.

Since new products (developed parts) are often adopted for new models,

seamless production of new part is verified.

![]()

Our glass assemblies will be assembled into a complete vehicle at our customer's factory,

and enjoyed by people all over the world.